Everyone knows about brainstorming, but have you ever heard of DesignStorming? This is a technique we use often at John MacDonald Architect (JMA). It helps to explore the infinite possibilities of a particular project by compiling solutions from different designers with different approaches and styles.

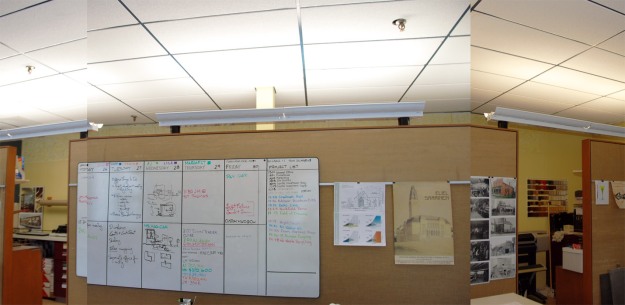

Our most recent DesignStorm was undertaken for a lighting project here in our office. Each designer was presented with the existing situation, which was 3 fluorescent light fixtures that run the length of our office. Designers where then given the task; these large, long lights required some form of stylish covering.

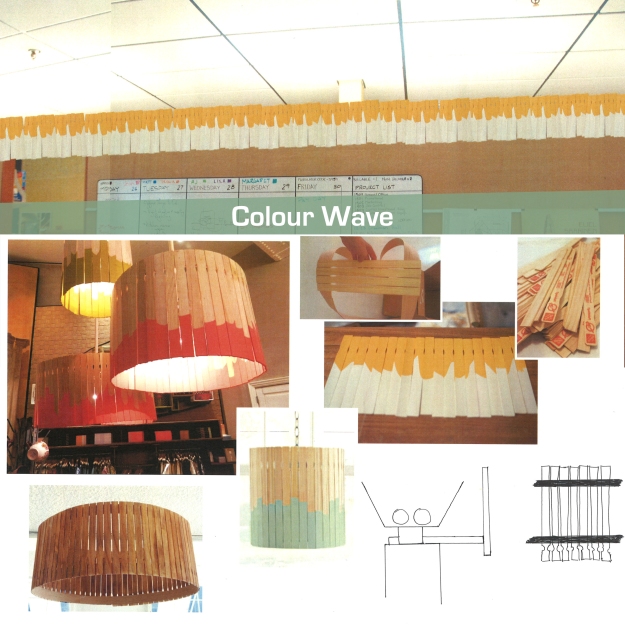

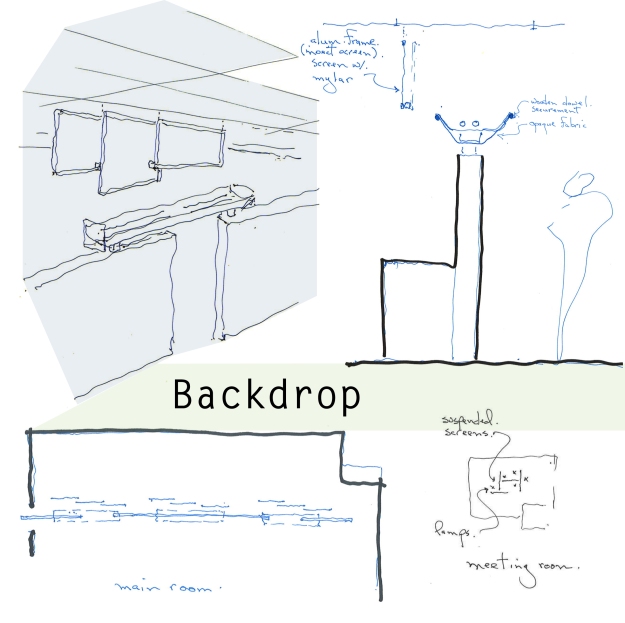

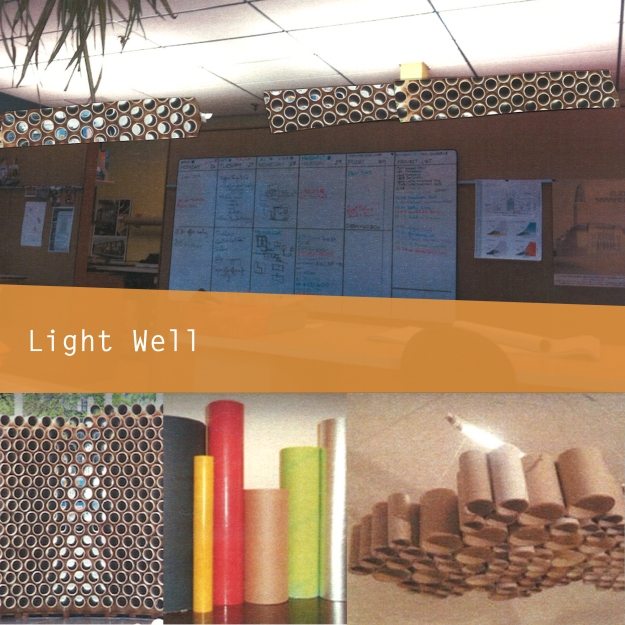

There where 6 designer and 4 days where given to prepare before each designer presented their idea. The process was to, come-up with a design, consider how to implement that design, create a short presentation and present it to the other designers and office. It is surprising the range of creativity and designs that where presented. See below for all 6 designs:

At JMA we believe that exploring several options and approaches is the key to successful results. We have done DesignStorms for several projects large and small, from a 3000 sq. ft. house to an office redesign, to a little cottage kitchen renovation. The results are always promising and a variety of resolutions are presented, but we call it a DesignStorm and not a Design Competition, because the final design is alway some form of mixing the designs into one, creating the very best possible solution. It is really a process that helps the client see the possibilities and to select the elements that best suite them and their needs.

The final design for our office fluorescent light fixtures, wrapping the outside of the fixture with a canvas material and caping the ends with a custom wood piece, keeping the feeling of openness between the main room and storage room. The final product is a tribute to the Canopy and Backdrop designs, merged into a new design that is practical, functional and attractive.